-

GT800 is the CNC machine boring from above best suited for carpentries that require flexibility, accuracy and high-quality end products.STANDARD EQUIPMENT• Head unit made up of independent spindles with 32 mm. centres• High-precision mechanical side reference.• Brushes on working table to avoid the storage of dust and shavings.• Panel movement with vacuum suction cup.HARDWARE & SOFTWARE• 7” touch-screen (optional 12”) with USB port.• Maggi custom software.• Linux operating system.• Up to 1000 working programs storable.MULTI-PURPOSE DRILLING MACHINE• Front holes.• Side holes.• Holes for hinges.• Multiple holes for shelves.Product Brochure

GT800 is the CNC machine boring from above best suited for carpentries that require flexibility, accuracy and high-quality end products.STANDARD EQUIPMENT• Head unit made up of independent spindles with 32 mm. centres• High-precision mechanical side reference.• Brushes on working table to avoid the storage of dust and shavings.• Panel movement with vacuum suction cup.HARDWARE & SOFTWARE• 7” touch-screen (optional 12”) with USB port.• Maggi custom software.• Linux operating system.• Up to 1000 working programs storable.MULTI-PURPOSE DRILLING MACHINE• Front holes.• Side holes.• Holes for hinges.• Multiple holes for shelves.Product Brochure -

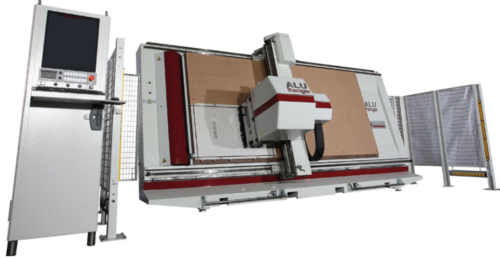

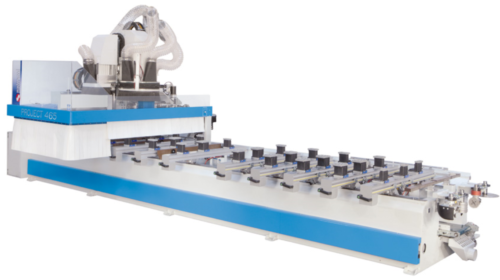

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1250mm 3800mm x 1550mm 3800mm x 1850mm 3800mm x 2100mm Product Brochure

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1250mm 3800mm x 1550mm 3800mm x 1850mm 3800mm x 2100mm Product Brochure -

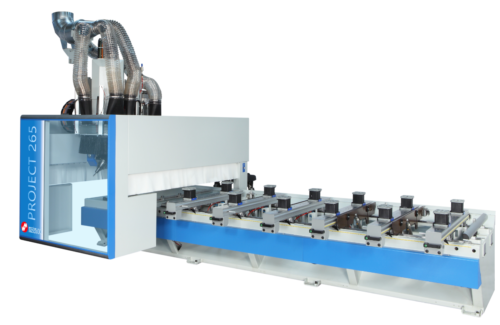

The CNC working center for high performance with small investment. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure

The CNC working center for high performance with small investment. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure -

5-axis machining centre with “big” features: large workpiece clearance, stiffness and high precision. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table - Equiped with Master SetUp, a new worktable “computeraided” setup system! Product Brochure

5-axis machining centre with “big” features: large workpiece clearance, stiffness and high precision. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table - Equiped with Master SetUp, a new worktable “computeraided” setup system! Product Brochure -

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table -

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table -

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table -

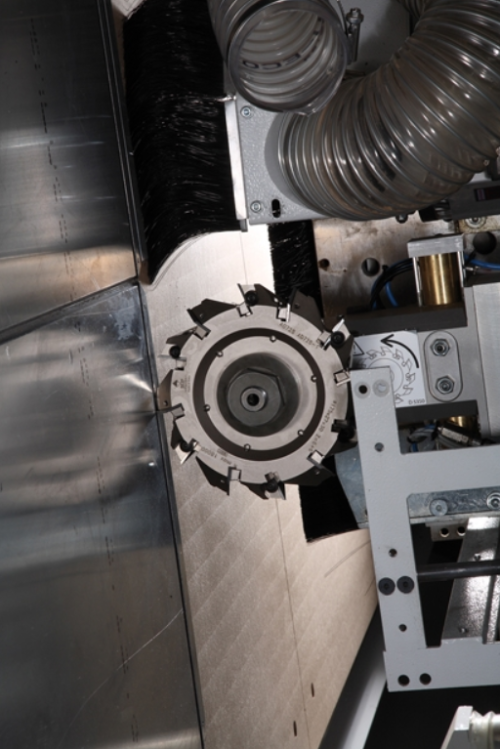

The small CNC boring machine for large jobs Versatile, easy and quick setting up Workpiece height up to 800mm Workpiece length Infinite Material Thickness 10 to 40mm Fully equiped drill head inc horizontals and saw blade Automatic tolerance correction for dimension dependant drilling (optional) - Ideal for workpieces which have already been edged Product Brochure

The small CNC boring machine for large jobs Versatile, easy and quick setting up Workpiece height up to 800mm Workpiece length Infinite Material Thickness 10 to 40mm Fully equiped drill head inc horizontals and saw blade Automatic tolerance correction for dimension dependant drilling (optional) - Ideal for workpieces which have already been edged Product Brochure