-

GT800 is the CNC machine boring from above best suited for carpentries that require flexibility, accuracy and high-quality end products.STANDARD EQUIPMENT• Head unit made up of independent spindles with 32 mm. centres• High-precision mechanical side reference.• Brushes on working table to avoid the storage of dust and shavings.• Panel movement with vacuum suction cup.HARDWARE & SOFTWARE• 7” touch-screen (optional 12”) with USB port.• Maggi custom software.• Linux operating system.• Up to 1000 working programs storable.MULTI-PURPOSE DRILLING MACHINE• Front holes.• Side holes.• Holes for hinges.• Multiple holes for shelves.Product Brochure

GT800 is the CNC machine boring from above best suited for carpentries that require flexibility, accuracy and high-quality end products.STANDARD EQUIPMENT• Head unit made up of independent spindles with 32 mm. centres• High-precision mechanical side reference.• Brushes on working table to avoid the storage of dust and shavings.• Panel movement with vacuum suction cup.HARDWARE & SOFTWARE• 7” touch-screen (optional 12”) with USB port.• Maggi custom software.• Linux operating system.• Up to 1000 working programs storable.MULTI-PURPOSE DRILLING MACHINE• Front holes.• Side holes.• Holes for hinges.• Multiple holes for shelves.Product Brochure -

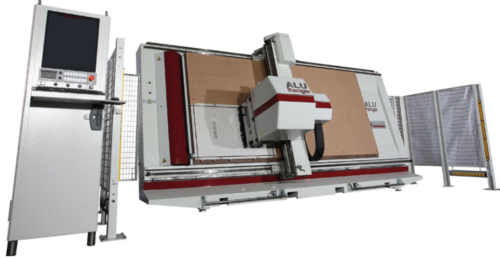

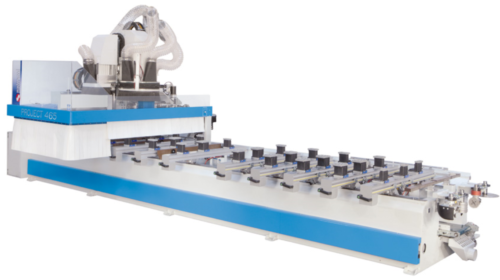

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1250mm 3800mm x 1550mm 3800mm x 1850mm 3800mm x 2100mm Product Brochure

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1250mm 3800mm x 1550mm 3800mm x 1850mm 3800mm x 2100mm Product Brochure -

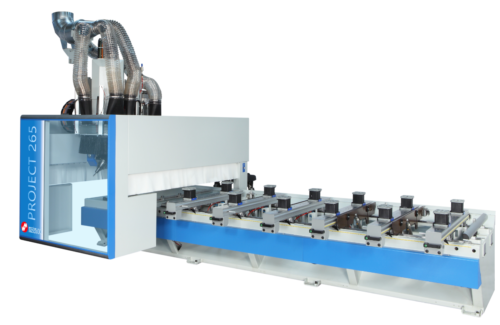

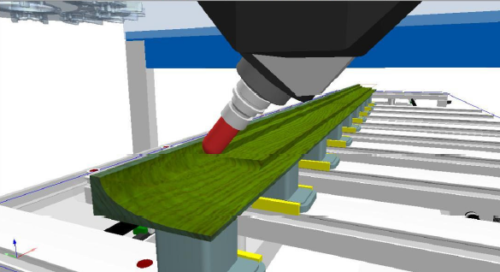

The CNC working center for high performance with small investment. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure

The CNC working center for high performance with small investment. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure -

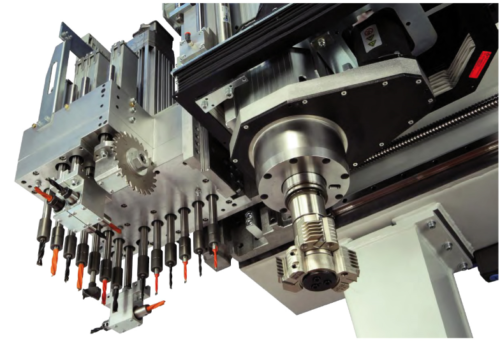

5-axis machining centre with “big” features: large workpiece clearance, stiffness and high precision. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table - Equiped with Master SetUp, a new worktable “computeraided” setup system! Product Brochure

5-axis machining centre with “big” features: large workpiece clearance, stiffness and high precision. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table - Equiped with Master SetUp, a new worktable “computeraided” setup system! Product Brochure -

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table -

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table -

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table -

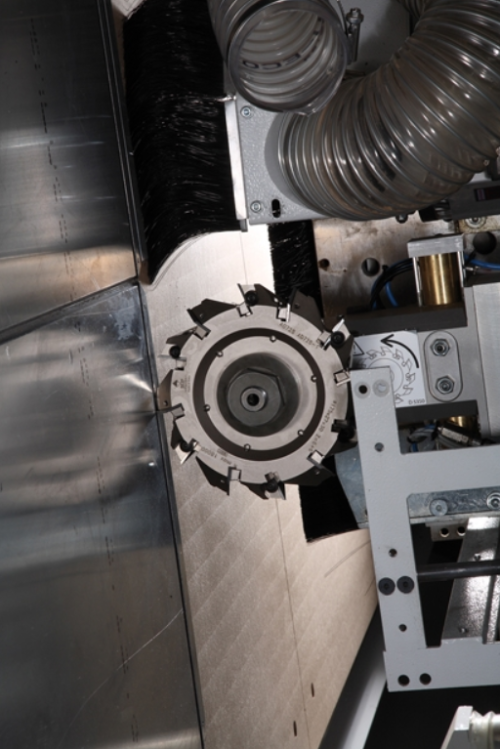

The small CNC boring machine for large jobs Versatile, easy and quick setting up Workpiece height up to 800mm Workpiece length Infinite Material Thickness 10 to 40mm Fully equiped drill head inc horizontals and saw blade Automatic tolerance correction for dimension dependant drilling (optional) - Ideal for workpieces which have already been edged Product Brochure

The small CNC boring machine for large jobs Versatile, easy and quick setting up Workpiece height up to 800mm Workpiece length Infinite Material Thickness 10 to 40mm Fully equiped drill head inc horizontals and saw blade Automatic tolerance correction for dimension dependant drilling (optional) - Ideal for workpieces which have already been edged Product Brochure -

The two-axis automatic mill cutter with numerical control, OMEC 650-A, is designed to indent dovetails and parallel indents for drawers and several furniture elements. Model 650-A is equipped with a spindle and a mill cutter that allow the production of indents of different heights. The machine is designed to cut single male or female workpieces, or both simultaneously. Pieces can be clamped and released in manual mode by means of pneumatic valves. The 650-A model is controlled by a CNC system that is programmed to manufacture two types of fixed pitch joints (25mm and 50mm). Product Brochure

The two-axis automatic mill cutter with numerical control, OMEC 650-A, is designed to indent dovetails and parallel indents for drawers and several furniture elements. Model 650-A is equipped with a spindle and a mill cutter that allow the production of indents of different heights. The machine is designed to cut single male or female workpieces, or both simultaneously. Pieces can be clamped and released in manual mode by means of pneumatic valves. The 650-A model is controlled by a CNC system that is programmed to manufacture two types of fixed pitch joints (25mm and 50mm). Product Brochure -

This model is equipped with a spindle unit and a milling cutter that can be used to manufacture joints of different heights. The "750CN" machine can process male pieces and female pieces both separately and in a combined mode. Pieces are locked and unlocked manually by means of specially designed pneumatic valves. Eight pneumatic cylinders guarantee the locking operation safely. The CNC system is designed to offer the maximum machining versatility and allows users to vary the pitch, number and depth of joints, as well as cutting speed, tool feed and tool diameter variation (this feature is used to adjust with a simple operation the coupling of male-to-female joints and to sharpen tools several times before replacing it). Product Brochure

-

The new generation of moulding and planing. The Powermat 700 is designed with a revolutionary new operating concept which no other moulder can offer. The result: improved ease of operation and very short setup times offer the highest degree of flexibility. With these outstanding qualities the new Powermat is the perfect response to the market demands of today and sets a new standard for four sided processing The Powermat 700 guarantees optimum interaction of tool and machine. From the cast-iron frame to the machine table and spindles, WEINIG represents optimal machining quality. This quality means that the process runs as smoothly as possible and this is reflected in the surface quality of the work pieces. This accuracy also guarantees precise profile production. Product Brochure

The new generation of moulding and planing. The Powermat 700 is designed with a revolutionary new operating concept which no other moulder can offer. The result: improved ease of operation and very short setup times offer the highest degree of flexibility. With these outstanding qualities the new Powermat is the perfect response to the market demands of today and sets a new standard for four sided processing The Powermat 700 guarantees optimum interaction of tool and machine. From the cast-iron frame to the machine table and spindles, WEINIG represents optimal machining quality. This quality means that the process runs as smoothly as possible and this is reflected in the surface quality of the work pieces. This accuracy also guarantees precise profile production. Product Brochure -

CNC Technology for Maximum Sawing Performance Professional Software Package Intelligent Clamps Double Side Aligners Security Package - for safe operation 10 Year Guarantee on All Linear Guides Saw Blade Protrusion: 105 mm Sawing Unit: up to 21 kW Cutting Lengths: up to 4,300 mm Cutting Widths: up to 4,250 mm Infinitely adjustable sawing unit feed rate: up to 130 m / min Sawing unit return speed: 150 m / min Positioning speed: 25 m / min (CE) Rip fence return speed: 100 m / min Product Brochure

CNC Technology for Maximum Sawing Performance Professional Software Package Intelligent Clamps Double Side Aligners Security Package - for safe operation 10 Year Guarantee on All Linear Guides Saw Blade Protrusion: 105 mm Sawing Unit: up to 21 kW Cutting Lengths: up to 4,300 mm Cutting Widths: up to 4,250 mm Infinitely adjustable sawing unit feed rate: up to 130 m / min Sawing unit return speed: 150 m / min Positioning speed: 25 m / min (CE) Rip fence return speed: 100 m / min Product Brochure -

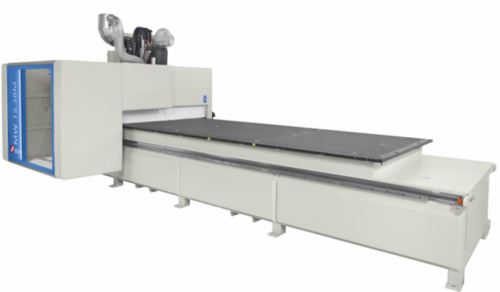

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure -

The small CNC boring machine for large jobs Versatile, easy and quick setting up Workpiece height up to 1000mm Workpiece length Infinite Material Thickness 10 to 60mm Including 3.3 kW HSK electrospindle - Including toolchanger Fully equiped drill head inc horizontals and saw blade Automatic tolerance correction for dimension dependant drilling (optional) - Ideal for workpieces which have already been edged Product Brochure

The small CNC boring machine for large jobs Versatile, easy and quick setting up Workpiece height up to 1000mm Workpiece length Infinite Material Thickness 10 to 60mm Including 3.3 kW HSK electrospindle - Including toolchanger Fully equiped drill head inc horizontals and saw blade Automatic tolerance correction for dimension dependant drilling (optional) - Ideal for workpieces which have already been edged Product Brochure -

FLEXIBLE AND EASY TO OPERATE TENONER The Pentho Compact 3 has a noise-reduced cut-off saw, tenon heads and one vertical spindle. The machine has a solid table on a stable vertical slide bar. The depth capacity of the machine is 150 mm. The table can be swivelled totally 60° in two directions. The machine comes with a 7" touch panel for the operation of the machine and starting of all motors

FLEXIBLE AND EASY TO OPERATE TENONER The Pentho Compact 3 has a noise-reduced cut-off saw, tenon heads and one vertical spindle. The machine has a solid table on a stable vertical slide bar. The depth capacity of the machine is 150 mm. The table can be swivelled totally 60° in two directions. The machine comes with a 7" touch panel for the operation of the machine and starting of all motors -

CNC machining center with 5 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure

CNC machining center with 5 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure -

FLEXIBLE AND EASY TO OPERATE TENONER The Pentho Compact 4 has a noise-reduced cut-off saw, tenon heads and two vertical spindles. The machine has a solid table on a stable vertical slide bar. The depth capacity of the machine is 150 mm. The table can be swivelled totally 60° in two directions. The machine comes with a 7" touch panel for the operation of the machine and starting of all motors

FLEXIBLE AND EASY TO OPERATE TENONER The Pentho Compact 4 has a noise-reduced cut-off saw, tenon heads and two vertical spindles. The machine has a solid table on a stable vertical slide bar. The depth capacity of the machine is 150 mm. The table can be swivelled totally 60° in two directions. The machine comes with a 7" touch panel for the operation of the machine and starting of all motors -

FLEXIBLE AND INTELLIGENT TENONER Use your set up time as productiontime The Pentho Compact has a noise-reduced cut-off saw, tenon heads and one vertical spindle. The machine has a solid table on a stable vertical slide bar. The depth capacity of the machine is 150 mm. The table can be swivelled totally 60° in two directions. The machine comes with a 7" touch panel in combination with electronic positions indicators Easy storing and recalling regular machine settings

FLEXIBLE AND INTELLIGENT TENONER Use your set up time as productiontime The Pentho Compact has a noise-reduced cut-off saw, tenon heads and one vertical spindle. The machine has a solid table on a stable vertical slide bar. The depth capacity of the machine is 150 mm. The table can be swivelled totally 60° in two directions. The machine comes with a 7" touch panel in combination with electronic positions indicators Easy storing and recalling regular machine settings -

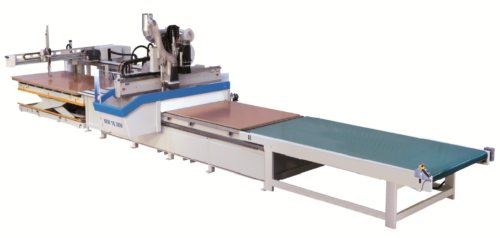

CNC machining center with 3/4 controlled axis equipped with automatic loading, labelling and automatic unloading for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm

CNC machining center with 3/4 controlled axis equipped with automatic loading, labelling and automatic unloading for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm -

OPTIMISE YOUR PRODUCTION TIME Intelligent Automatic Table The Pentho Compact has a noise-reduced cut-off saw, tenon heads and one vertical spindle. The machine has a solid table on a stable vertical slide bar. The depth capacity of the machine is 150 mm. The table can be swivelled totally 60° in two directions. The machine comes with a 7" touch panel in combination with electronic positions indicators Easy storing and recalling regular machine settings 200mm Spindle Length 7.5 kw Motor

OPTIMISE YOUR PRODUCTION TIME Intelligent Automatic Table The Pentho Compact has a noise-reduced cut-off saw, tenon heads and one vertical spindle. The machine has a solid table on a stable vertical slide bar. The depth capacity of the machine is 150 mm. The table can be swivelled totally 60° in two directions. The machine comes with a 7" touch panel in combination with electronic positions indicators Easy storing and recalling regular machine settings 200mm Spindle Length 7.5 kw Motor