- Capacity: 50L

- POWER: 1200W∕1400W

- Voltage: 220V-240V

- Frequency: 50Hz/60Hz

- Suction hose length: 1.5m

- Air flow rate: 40L/S

- vacuum: >≥17KPa

- Noise: 78-80dB(A)

- Blower function

- Hose diameter :38mm

- Length of cable:4.5m

- Dimensions: 800 X 350 mm

-

Fitted with a High Efficiency Particulate Air (HEPA) filter as an additional stage of filtration for harmful, irritant or allergenic substances.

Fitted with a High Efficiency Particulate Air (HEPA) filter as an additional stage of filtration for harmful, irritant or allergenic substances. -

The powerful-shredder AZR 60 Primus, with its wide range of applications, can be shred many different wood materials such as softwood, chipboard, as well as paper and cardboard.A special feature of the series AZR 60 Primus is the low noise and power consumption associated with low rotor speed.The material is feeded to the hopper and crushed between the rotor blades and the fixed counter knife into chips. The chip size is determined by the screen perforation size.The PLC control switches off the machine automatically when the hopper is empty. The produced chips will be held for example by a screw conveyor from the machine and sent for thermal recovery. By bulky materials an enormous volume reduction is achieved.- High output- Easy to use and very reliable- Compact, rugged steel construction- Easy maintenance- Low operating costs

The powerful-shredder AZR 60 Primus, with its wide range of applications, can be shred many different wood materials such as softwood, chipboard, as well as paper and cardboard.A special feature of the series AZR 60 Primus is the low noise and power consumption associated with low rotor speed.The material is feeded to the hopper and crushed between the rotor blades and the fixed counter knife into chips. The chip size is determined by the screen perforation size.The PLC control switches off the machine automatically when the hopper is empty. The produced chips will be held for example by a screw conveyor from the machine and sent for thermal recovery. By bulky materials an enormous volume reduction is achieved.- High output- Easy to use and very reliable- Compact, rugged steel construction- Easy maintenance- Low operating costs -

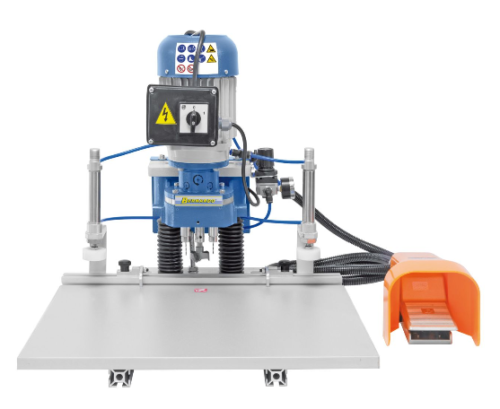

Technical Specifications Drill diameter 35 mm No. of spindles 3 pcs Control manual Workpiece clamping manual Distance table/spindle max. 85 mm Technical Specifications Drill diameter 35 mm No. of spindles 3 pcs Control manual Workpiece clamping manual Distance table/spindle max. 85 mm Distance table/drill max. 50 mm Table size 500 x 350 mm Table moveable 105 mm Fence length (incl. extension) 500 mm Speed 3000 rpm Motor power 0,75 kW Voltage230 V Machine dimension (W x D x H)500 x 500 x 520 mm Weight approx. 19 kg

Price: €925 + VAT - this is a special price and for a limited time & includes delivery throughout Ireland

-

Technical Specifications Drill diameter 35 mm No. of spindles 3 pcs Control pneumatic Workpiece clamping pneumatic Distance table/spindle max. 85 mm Distance table/drill max. 50 mm Table size 500 x 350 mm Table moveable 105 mm Fence length (incl. extension) 500 mm Compressed Air required 6-8 bar Speed 3000 rpm Motor power 0,75 kW Voltage 230 V Machine dimension (W x D x H) 500 x 500 x 520 mm

Technical Specifications Drill diameter 35 mm No. of spindles 3 pcs Control pneumatic Workpiece clamping pneumatic Distance table/spindle max. 85 mm Distance table/drill max. 50 mm Table size 500 x 350 mm Table moveable 105 mm Fence length (incl. extension) 500 mm Compressed Air required 6-8 bar Speed 3000 rpm Motor power 0,75 kW Voltage 230 V Machine dimension (W x D x H) 500 x 500 x 520 mm -

When it is a matter of lifting and lowering loads in order to bring the loads to optimum working heights, the lifting table is outstanding. Precise and stepless raising and lowering are controlled by a centrally located foot pedal. The rate of descent is constant whether there is minimum or maximum weight of the lift. The NIVEAU lifting tables assist in all kinds of manufacturing processes and also allow for ergonomic working, as health hazards such as lifting injuries are posed by workers manually lifting loads. Product Brochure

-

The ADM 260 planer and thicknesser is a powerful, solid machine which is well established among craftsmen. The centrally guided thicknessing table and torsion-free planing tables guarantee precise results. Switch-plug combination with motor brake as standard Planing tables can be tilted into upright position for a quick conversion to thicknessing Integrated, tiltable dust hood (outlet Ø 100 mm)

-

Tiltable planing tables for quick conversion to thicknessing Integrated tiltable dust hood, outlet Ø 1oo mm Both planing tables feature fine adjustment and noise absorbing slots Maintenance-free 4-knife cutterblock with 18% quality HSS- knives Spiral toothed infeed roller for safe and consistent workpiece infeed

-

Comes standard with 2 cutting speeds. Dynamically balanced flywheels for smooth run Cutting speed adjustable with V-belt to the workpiece Cutting height adjustment via gear rack with mm-scale using a handwheel Working table with grounded surface and T-slot for the mitre fence Easy bandsaw blade change using the quick clamping lever on the backside.

Comes standard with 2 cutting speeds. Dynamically balanced flywheels for smooth run Cutting speed adjustable with V-belt to the workpiece Cutting height adjustment via gear rack with mm-scale using a handwheel Working table with grounded surface and T-slot for the mitre fence Easy bandsaw blade change using the quick clamping lever on the backside. -

Torsion-free machine body guarantees for a smooth and precise run Aluminium die-casting flywheels with special rubber-coating for a long life span of the bandsaw blades Generously dimensioned cast iron table, tiltable from -10° to +45° Serially with 2 dust extraction outlets (diam. 100 mm) for an optimal dust extraction Cutting height adjustment via gear rack with mm-scale using a handwheel

Torsion-free machine body guarantees for a smooth and precise run Aluminium die-casting flywheels with special rubber-coating for a long life span of the bandsaw blades Generously dimensioned cast iron table, tiltable from -10° to +45° Serially with 2 dust extraction outlets (diam. 100 mm) for an optimal dust extraction Cutting height adjustment via gear rack with mm-scale using a handwheel -

The FKS 1600 N sliding table saw meets the requirements of professional users, such as precision, high work comfort, short conversion time and versatility. Characteristics include high quality finish, smooth-running sliding table plus rip fence featuring round rod guide and fine adjustment.

- Smooth running, precise sliding table with hardened, prism-shaped guide

- Solid square table for operating on heavy, oversize sheet materials