-

The HCL 1200 lathe features an electronic, steplessly adjustable speed setting as part of the standard accessories which allows ideal adjustment to each workpiece diameter - predominantely used among experienced, high-level amateurs. Quick clamping lever ensures fast clamping of tailstock to machine bed Outboard turning attachment optionally available for processing of oversize work pieces

-

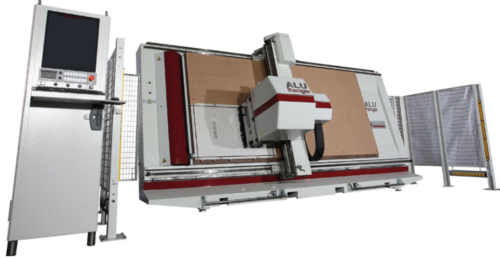

- Solid square table helps support large and heavy sheet material

- Extractable telescopic fence (up to 2260 mm), mountable at front or rear of square table

- Powerful drive motor guarantees optimal cutting capacity even at continuous operation

- Complete with table extensions in width and length for better support of large sheet material

-

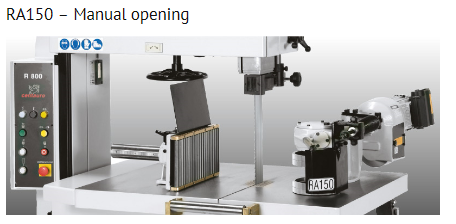

The T 800 F is a reliable spindle moulder with tilting spindle providing outstanding quality at a relatively low cost. The extensive range of applications and optimal work comfort were factored into the design of this model, as well as high safety standards and a user-friendly operating method. Smooth sliding table allows for easier processing of oversize workpieces Solid protective hood features finely adjustable aluminium fence rails Quick and easy readout of spindle speed on digital display

-

Semiautomatic boring machine equipped with n.2 parallel vertical boring heads. Machine for vertical boring, expressly designed to execute holes in a line and particularly suited for the bookcase and wardrobe-side processing. Quick, precise and easy setting-up. Product Brochure

-

The Casadei PFS 520 combined surface/thickness planer has been designed for craftsmen and carpenters who require a high performance machine but only have a limited space available.

ADVANTAGES

Flexibility: Lifting of both surface tables is simultaneous with adjustment over a link and rod system. Automatic positioning of cutterhead protection and dust extraction hood. A locking knob enables quick changeover from surfacing to thicknessing.

Reliability: Large dimension thicknessing table mounted on 4 steel raising screws protected against dust by bellows.

Sturdiness: Machine frame of notable thickness and solid construction. Planer unit with infeed anti-kickback fingers and segmented chipbreakers, serrated steel infeed roller with spiral teeth and rubber coated outfeed roller.

-

STANDARD VERSION

- Adjustable or fixed fence with wooden support tables (depending on machine version)

- Mechanical digital readout of working height with decimal control on the vertical shaft movement

- Safety micro-switches on motor access door

- Emergency pushbutton

- Padlockable main switch

- Overload switch protection

- Direct start main motor

- Reverse spindle rotation

- Auxiliary low voltage circuit (110 Volts)

-

Heavy duty operation, reliability, ergonomics and ease of use are the main features that make the F 230 an advanced product, unbeatable in its category. The complete standard configuration and the wide choice of options make the F 235 A a machine for the most demanding users. The tilting spindle ± 45,5° makes the F 255 a machine extremely flexible and versatile. The broad choice of options together with the tilting spindle, make the machine suitable to any working requirement. Product Brochure

-

Casadei PF 410 Surface Planer

STANDARD

- Overhead control panel, easy to reach by the operator

- Ribbed cast iron

- Movement of surface tables on connecting bars

- Spindle with knifes setting device

- Planer protection

- Manual movement of infeed table

- Readout of cutting depth on scale

- Direct start main motor

- Padlockable main switch

- Overload switch protection

- Auxiliary low voltage circuit (110 Volt)

- Bridge type cutterblock protection

- Rebating not allowed

- Automatic brake on motor

- E.C. certificate of conformity

-

Casadei PF 520M Surface planer

STANDARD VERSION

- Upper control panel, easy to reach by the operator

- Ribbed cast iron

- Movement of surface tables on connecting bars

- Powered movement of infeed table

- Electronic digital readout of cutting depth

- Spindle with knifes setting device

- Planer protection

- Direct start main motor

- Padlockable main switch

- Emergency push button

- Overload switch protection

- Auxiliary low voltage circuit (110 Volts)

- Bridge type cutterblock protection

- Automatic brake on motor

- E.C. certificate of conformity

-

4 controlled axis (X-Y axis and blade rotation). 3-wheel bandsaw, 800 mm. dia. Bandsaw motor KW 9,2 (HP12,5) Pneumatic sawblade tension. Sawblade rotation -90° +90°. Top and bottom precision guide. 2 clamps (max lenght 170 mm). Mini laser. Software for cuts programming. Feed table / Guard and safety booth. Product Brochure

4 controlled axis (X-Y axis and blade rotation). 3-wheel bandsaw, 800 mm. dia. Bandsaw motor KW 9,2 (HP12,5) Pneumatic sawblade tension. Sawblade rotation -90° +90°. Top and bottom precision guide. 2 clamps (max lenght 170 mm). Mini laser. Software for cuts programming. Feed table / Guard and safety booth. Product Brochure -

Centauro B.V.M. NC Controlled Chisel Morticer with 3 Controlled axes Programmable hollow square chisel head available on request Y-axis Stroke 250mm X-axis Stroke 1100mm Z-axis Stroke 100mm All axes are controlled by “Brushless” motors – axis traverse on guides with Sliding Blocks and Lead Screw with precision re-circulating balls

-

The bandsaw frame is of welded steel and the sawblade is completely guarded. The disc-type wheels in cast-iron are experterly balanced and run on sealed for life ball bearings. Cast-iron table tilting up-to 45° (20° CE) to the right. Telescopic guard for total blade protection. Automatic braking of wheels (CE): Self-braking motor forØ 600/700 mm and pneumatic braking for Ø 800/900 mm. (Footbrake for Non-CE version). Motor protection switch with release coil (CE). Key-locking doors - and much more.... Product Brochure

The bandsaw frame is of welded steel and the sawblade is completely guarded. The disc-type wheels in cast-iron are experterly balanced and run on sealed for life ball bearings. Cast-iron table tilting up-to 45° (20° CE) to the right. Telescopic guard for total blade protection. Automatic braking of wheels (CE): Self-braking motor forØ 600/700 mm and pneumatic braking for Ø 800/900 mm. (Footbrake for Non-CE version). Motor protection switch with release coil (CE). Key-locking doors - and much more.... Product Brochure -

Automatic star-delta starter. Pneumatic disc braking system Motor protection switch with no volt release Digital Ampmeter Front infeed rollers with emergency protection cable Safety micro-switches to doors Fixed working table in steel Chaco inserts blade guide on working table Rackwork and telescopic blade guide Cleaning scrapers on wheels Sawblade tension indicator Sawblade cleaning felt with diesel oil tank Equiped with steel sawblade ready for use. Internal and external sawblade lubrification Hydraulic speed variator 0-40mt/min Optical sensor Diameter of saw wheels 1000mm Max. cutting height 550mm Max.cutting width 970mm Max. blade width 100mm Motor power 30hp (40 HP Optional) Product Brouchure

Automatic star-delta starter. Pneumatic disc braking system Motor protection switch with no volt release Digital Ampmeter Front infeed rollers with emergency protection cable Safety micro-switches to doors Fixed working table in steel Chaco inserts blade guide on working table Rackwork and telescopic blade guide Cleaning scrapers on wheels Sawblade tension indicator Sawblade cleaning felt with diesel oil tank Equiped with steel sawblade ready for use. Internal and external sawblade lubrification Hydraulic speed variator 0-40mt/min Optical sensor Diameter of saw wheels 1000mm Max. cutting height 550mm Max.cutting width 970mm Max. blade width 100mm Motor power 30hp (40 HP Optional) Product Brouchure -

Automatic star-delta starter. Pneumatic wheel braking. Steel-table, tilting upto 15°. Top and bottom guide with wooden blocks. Sawblade tension indicator. Sawblade cleaning and cooling felt. Equiped with steel sawblade ready for use. Diameter of saw wheels 800mm Max. cutting height 400mm Max.cutting width 780mm Max. blade width 80mm Motor power 15hp (20 HP Optional) Available with a choice of 4 different feed units Product Brouchure

Automatic star-delta starter. Pneumatic wheel braking. Steel-table, tilting upto 15°. Top and bottom guide with wooden blocks. Sawblade tension indicator. Sawblade cleaning and cooling felt. Equiped with steel sawblade ready for use. Diameter of saw wheels 800mm Max. cutting height 400mm Max.cutting width 780mm Max. blade width 80mm Motor power 15hp (20 HP Optional) Available with a choice of 4 different feed units Product Brouchure -

Cast-iron table tilting up-to 45° (20° CE) to the right. Total blade protection. Automatic braking of wheels (CE). Footbrake for Non-CE version, except SP 400 Motor protection switch with release coil (CE). Key-locking doors. Sawblade tension indicator. Rackwork for raising and lowering the top guide Product Brochure

Cast-iron table tilting up-to 45° (20° CE) to the right. Total blade protection. Automatic braking of wheels (CE). Footbrake for Non-CE version, except SP 400 Motor protection switch with release coil (CE). Key-locking doors. Sawblade tension indicator. Rackwork for raising and lowering the top guide Product Brochure -

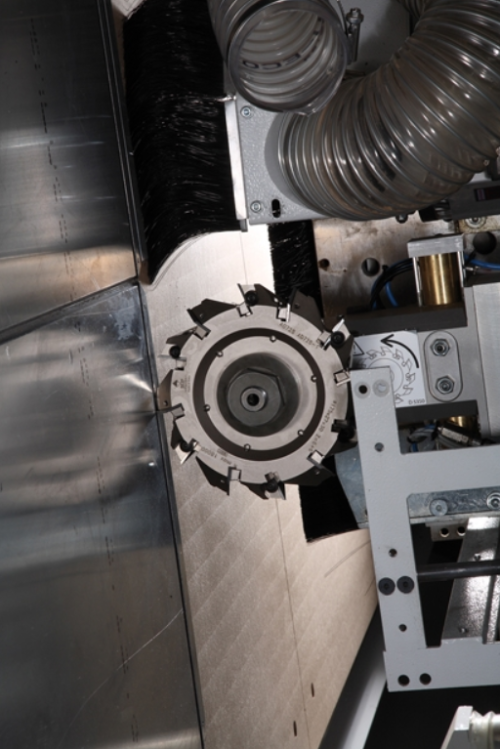

Large table surface: When machining large panels, the table surface is determinating. With the HX310 you have a major advantage. Spindle arbor: Standard spindle diameter is 30 mm (optional 50 mm or 1 1/4"), the working length is 120 mm, the up-and- down stroke is 140 mm. The up and down stroke is 140 mm.