-

Bowmould Master Spindle Moulder Guard - is a patented modular fing fence system that allows fast safe machining on curved work. It can be used either left hand or right hand machining. The unit is supplied with infinitely adjustable infeed guide, dust shields suitable for tools with diameters up to 220mm. Suitable for either hand or power feed use with integral vertical pressure guard.

-

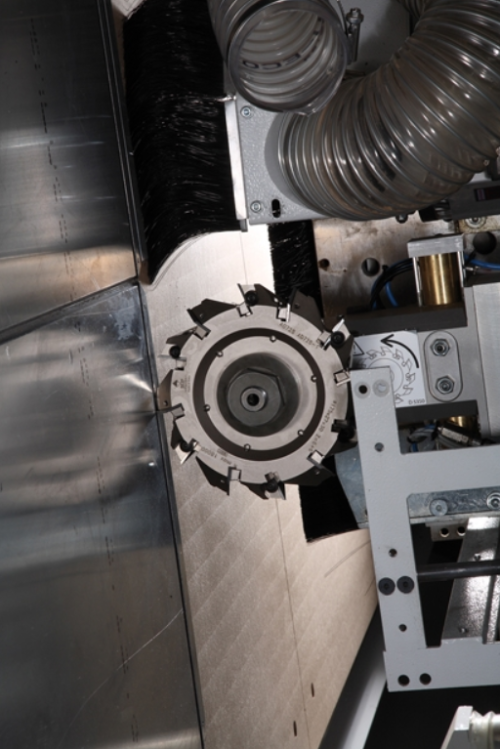

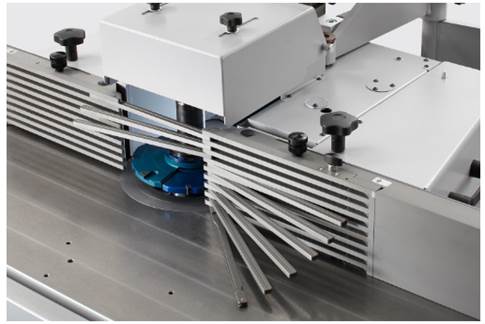

The fence opening should always be closed as much as possible, so that the workpiece can be safely guided and slide along the fence. Both are provided by the tried-and-tested Aigner Integral fence. The bars of the jaws consist of hard-coated aluminium and can be easily folded in position, released and also varied in height. The height of the bar cassettes is adjustable and they are easy to remove to enable working with a wooden insert.

The fence opening should always be closed as much as possible, so that the workpiece can be safely guided and slide along the fence. Both are provided by the tried-and-tested Aigner Integral fence. The bars of the jaws consist of hard-coated aluminium and can be easily folded in position, released and also varied in height. The height of the bar cassettes is adjustable and they are easy to remove to enable working with a wooden insert. -

Designed for the smaller workshop in industry, schools and colleges, the Unit Dust Filter provides a cost-effective solution to dust control of sanders, band saws, circular saws, linishers, etc. The Unit Dust Filter is available in 11 models ranging from 1 sleeve to 33 sleeves, from 1020m³ per hour to 5100m³ per hour. The Unit Dust Filter can be supplied clad or unclad and can be wheeled for portable workshop control or sited externally if space is at a premium.

-

Fitted with a High Efficiency Particulate Air (HEPA) filter as an additional stage of filtration for harmful, irritant or allergenic substances.

Fitted with a High Efficiency Particulate Air (HEPA) filter as an additional stage of filtration for harmful, irritant or allergenic substances.- Tank Material: Stainless steel

- Capacity: 60L

- POWER: 1200W∕1400W x 2

- Voltage: 220V-240V

- Frequency: 50Hz/60Hz

- Suction hose length: 1.5m

- Air flow rate: 50L/S

- vacuum: >≥17KPa

- Noise: 78-80dB(A)

- Hose diameter :38mm

- Length of cable:4.5m

- Dimensions: 600 X 560 x 780 mm

-

Fitted with a High Efficiency Particulate Air (HEPA) filter as an additional stage of filtration for harmful, irritant or allergenic substances.

Fitted with a High Efficiency Particulate Air (HEPA) filter as an additional stage of filtration for harmful, irritant or allergenic substances.- Tank Material: Stainless steel

- Capacity: 80L

- POWER: 1200W∕1400W x 2

- Voltage: 220V-240V

- Frequency: 50Hz/60Hz

- Suction hose length: 1.5m

- Air flow rate: 50L/S

- vacuum: >≥17KPa

- Noise: 78-80dB(A)

- Hose diameter :38mm

- Length of cable:4.5m

- Dimensions: 600 X 540 x 945 mm

-

Fitted with a High Efficiency Particulate Air (HEPA) filter as an additional stage of filtration for harmful, irritant or allergenic substances.

Fitted with a High Efficiency Particulate Air (HEPA) filter as an additional stage of filtration for harmful, irritant or allergenic substances.- Capacity: 50L

- POWER: 1200W∕1400W

- Voltage: 220V-240V

- Frequency: 50Hz/60Hz

- Suction hose length: 1.5m

- Air flow rate: 40L/S

- vacuum: >≥17KPa

- Noise: 78-80dB(A)

- Blower function

- Hose diameter :38mm

- Length of cable:4.5m

- Dimensions: 800 X 350 mm

-

The powerful-shredder AZR 60 Primus, with its wide range of applications, can be shred many different wood materials such as softwood, chipboard, as well as paper and cardboard.A special feature of the series AZR 60 Primus is the low noise and power consumption associated with low rotor speed.The material is feeded to the hopper and crushed between the rotor blades and the fixed counter knife into chips. The chip size is determined by the screen perforation size.The PLC control switches off the machine automatically when the hopper is empty. The produced chips will be held for example by a screw conveyor from the machine and sent for thermal recovery. By bulky materials an enormous volume reduction is achieved.- High output- Easy to use and very reliable- Compact, rugged steel construction- Easy maintenance- Low operating costs

The powerful-shredder AZR 60 Primus, with its wide range of applications, can be shred many different wood materials such as softwood, chipboard, as well as paper and cardboard.A special feature of the series AZR 60 Primus is the low noise and power consumption associated with low rotor speed.The material is feeded to the hopper and crushed between the rotor blades and the fixed counter knife into chips. The chip size is determined by the screen perforation size.The PLC control switches off the machine automatically when the hopper is empty. The produced chips will be held for example by a screw conveyor from the machine and sent for thermal recovery. By bulky materials an enormous volume reduction is achieved.- High output- Easy to use and very reliable- Compact, rugged steel construction- Easy maintenance- Low operating costs -

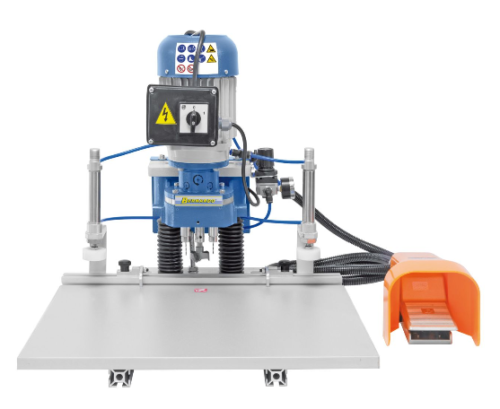

Technical Specifications Drill diameter 35 mm No. of spindles 3 pcs Control manual Workpiece clamping manual Distance table/spindle max. 85 mm Technical Specifications Drill diameter 35 mm No. of spindles 3 pcs Control manual Workpiece clamping manual Distance table/spindle max. 85 mm Distance table/drill max. 50 mm Table size 500 x 350 mm Table moveable 105 mm Fence length (incl. extension) 500 mm Speed 3000 rpm Motor power 0,75 kW Voltage230 V Machine dimension (W x D x H)500 x 500 x 520 mm Weight approx. 19 kg

Price: €925 + VAT - this is a special price and for a limited time & includes delivery throughout Ireland

-

Technical Specifications Drill diameter 35 mm No. of spindles 3 pcs Control pneumatic Workpiece clamping pneumatic Distance table/spindle max. 85 mm Distance table/drill max. 50 mm Table size 500 x 350 mm Table moveable 105 mm Fence length (incl. extension) 500 mm Compressed Air required 6-8 bar Speed 3000 rpm Motor power 0,75 kW Voltage 230 V Machine dimension (W x D x H) 500 x 500 x 520 mm

Technical Specifications Drill diameter 35 mm No. of spindles 3 pcs Control pneumatic Workpiece clamping pneumatic Distance table/spindle max. 85 mm Distance table/drill max. 50 mm Table size 500 x 350 mm Table moveable 105 mm Fence length (incl. extension) 500 mm Compressed Air required 6-8 bar Speed 3000 rpm Motor power 0,75 kW Voltage 230 V Machine dimension (W x D x H) 500 x 500 x 520 mm -

When it is a matter of lifting and lowering loads in order to bring the loads to optimum working heights, the lifting table is outstanding. Precise and stepless raising and lowering are controlled by a centrally located foot pedal. The rate of descent is constant whether there is minimum or maximum weight of the lift. The NIVEAU lifting tables assist in all kinds of manufacturing processes and also allow for ergonomic working, as health hazards such as lifting injuries are posed by workers manually lifting loads. Product Brochure

-

The ADM 260 planer and thicknesser is a powerful, solid machine which is well established among craftsmen. The centrally guided thicknessing table and torsion-free planing tables guarantee precise results. Switch-plug combination with motor brake as standard Planing tables can be tilted into upright position for a quick conversion to thicknessing Integrated, tiltable dust hood (outlet Ø 100 mm)

-

Tiltable planing tables for quick conversion to thicknessing Integrated tiltable dust hood, outlet Ø 1oo mm Both planing tables feature fine adjustment and noise absorbing slots Maintenance-free 4-knife cutterblock with 18% quality HSS- knives Spiral toothed infeed roller for safe and consistent workpiece infeed

-

Comes standard with 2 cutting speeds. Dynamically balanced flywheels for smooth run Cutting speed adjustable with V-belt to the workpiece Cutting height adjustment via gear rack with mm-scale using a handwheel Working table with grounded surface and T-slot for the mitre fence Easy bandsaw blade change using the quick clamping lever on the backside.

Comes standard with 2 cutting speeds. Dynamically balanced flywheels for smooth run Cutting speed adjustable with V-belt to the workpiece Cutting height adjustment via gear rack with mm-scale using a handwheel Working table with grounded surface and T-slot for the mitre fence Easy bandsaw blade change using the quick clamping lever on the backside. -

Torsion-free machine body guarantees for a smooth and precise run Aluminium die-casting flywheels with special rubber-coating for a long life span of the bandsaw blades Generously dimensioned cast iron table, tiltable from -10° to +45° Serially with 2 dust extraction outlets (diam. 100 mm) for an optimal dust extraction Cutting height adjustment via gear rack with mm-scale using a handwheel

Torsion-free machine body guarantees for a smooth and precise run Aluminium die-casting flywheels with special rubber-coating for a long life span of the bandsaw blades Generously dimensioned cast iron table, tiltable from -10° to +45° Serially with 2 dust extraction outlets (diam. 100 mm) for an optimal dust extraction Cutting height adjustment via gear rack with mm-scale using a handwheel -

The FKS 1600 N sliding table saw meets the requirements of professional users, such as precision, high work comfort, short conversion time and versatility. Characteristics include high quality finish, smooth-running sliding table plus rip fence featuring round rod guide and fine adjustment.

- Smooth running, precise sliding table with hardened, prism-shaped guide

- Solid square table for operating on heavy, oversize sheet materials

-

The HCL 1200 lathe features an electronic, steplessly adjustable speed setting as part of the standard accessories which allows ideal adjustment to each workpiece diameter - predominantely used among experienced, high-level amateurs. Quick clamping lever ensures fast clamping of tailstock to machine bed Outboard turning attachment optionally available for processing of oversize work pieces

-

- Solid square table helps support large and heavy sheet material

- Extractable telescopic fence (up to 2260 mm), mountable at front or rear of square table

- Powerful drive motor guarantees optimal cutting capacity even at continuous operation

- Complete with table extensions in width and length for better support of large sheet material

-

The T 800 F is a reliable spindle moulder with tilting spindle providing outstanding quality at a relatively low cost. The extensive range of applications and optimal work comfort were factored into the design of this model, as well as high safety standards and a user-friendly operating method. Smooth sliding table allows for easier processing of oversize workpieces Solid protective hood features finely adjustable aluminium fence rails Quick and easy readout of spindle speed on digital display

-

Semiautomatic boring machine equipped with n.2 parallel vertical boring heads. Machine for vertical boring, expressly designed to execute holes in a line and particularly suited for the bookcase and wardrobe-side processing. Quick, precise and easy setting-up. Product Brochure

-

The Casadei PFS 520 combined surface/thickness planer has been designed for craftsmen and carpenters who require a high performance machine but only have a limited space available.

ADVANTAGES

Flexibility: Lifting of both surface tables is simultaneous with adjustment over a link and rod system. Automatic positioning of cutterhead protection and dust extraction hood. A locking knob enables quick changeover from surfacing to thicknessing.

Reliability: Large dimension thicknessing table mounted on 4 steel raising screws protected against dust by bellows.

Sturdiness: Machine frame of notable thickness and solid construction. Planer unit with infeed anti-kickback fingers and segmented chipbreakers, serrated steel infeed roller with spiral teeth and rubber coated outfeed roller.

-

STANDARD VERSION

- Adjustable or fixed fence with wooden support tables (depending on machine version)

- Mechanical digital readout of working height with decimal control on the vertical shaft movement

- Safety micro-switches on motor access door

- Emergency pushbutton

- Padlockable main switch

- Overload switch protection

- Direct start main motor

- Reverse spindle rotation

- Auxiliary low voltage circuit (110 Volts)

-

Heavy duty operation, reliability, ergonomics and ease of use are the main features that make the F 230 an advanced product, unbeatable in its category. The complete standard configuration and the wide choice of options make the F 235 A a machine for the most demanding users. The tilting spindle ± 45,5° makes the F 255 a machine extremely flexible and versatile. The broad choice of options together with the tilting spindle, make the machine suitable to any working requirement. Product Brochure

-

Casadei PF 410 Surface Planer

STANDARD

- Overhead control panel, easy to reach by the operator

- Ribbed cast iron

- Movement of surface tables on connecting bars

- Spindle with knifes setting device

- Planer protection

- Manual movement of infeed table

- Readout of cutting depth on scale

- Direct start main motor

- Padlockable main switch

- Overload switch protection

- Auxiliary low voltage circuit (110 Volt)

- Bridge type cutterblock protection

- Rebating not allowed

- Automatic brake on motor

- E.C. certificate of conformity

-

Casadei PF 520M Surface planer

STANDARD VERSION

- Upper control panel, easy to reach by the operator

- Ribbed cast iron

- Movement of surface tables on connecting bars

- Powered movement of infeed table

- Electronic digital readout of cutting depth

- Spindle with knifes setting device

- Planer protection

- Direct start main motor

- Padlockable main switch

- Emergency push button

- Overload switch protection

- Auxiliary low voltage circuit (110 Volts)

- Bridge type cutterblock protection

- Automatic brake on motor

- E.C. certificate of conformity