Performance, flexibility, modularity and economy all concentrated in a 3 axis working center.

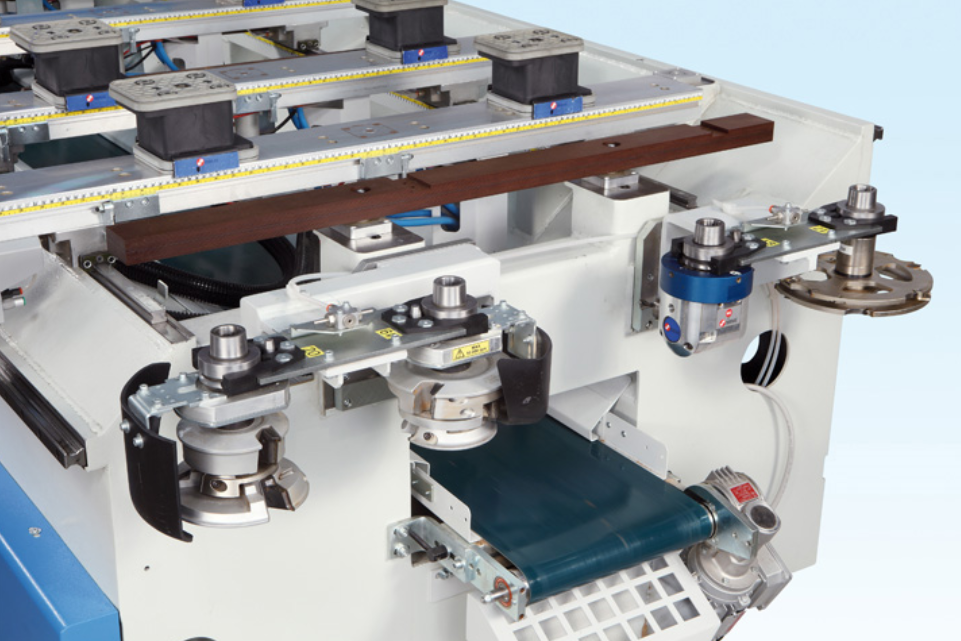

“TUBELESS” TYPE WORKING TABLE

Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail

No risk of damaging pipes during machining

Time saving set up of work table