Woodworking Machinery – Safety Guards and Fences

Guarding is the most effective means of reducing the risk of injury or harm from dangerous parts of a machine. In its simplest form, guarding is a physical barrier preventing access to any part of a machine that has the potential to cut,

pierce, graze or crush a person or a body part. Guarding can be designed and manufactured as part of a machine or it can be designed and manufactured as a separate part. Many types of guarding systems are available to protect workers from dangerous machinery. If guarding is used as a control measure, it should, as far as practicable, prevent access to the danger points or dangerous areas of the machine. Effective guards protect workers from preventable injuries. The guards should not be removed or disabled unless it is necessary for cleaning, repair or maintenance, and only then in accordance with agreed (and preferably written) safe procedures that prevent operation or unintentional start-up. The operators of the machines and other employees should be involved in developing these procedures, and be trained to carry them out.

-

Bowmould Master Spindle Moulder Guard - is a patented modular fing fence system that allows fast safe machining on curved work. It can be used either left hand or right hand machining. The unit is supplied with infinitely adjustable infeed guide, dust shields suitable for tools with diameters up to 220mm. Suitable for either hand or power feed use with integral vertical pressure guard.

-

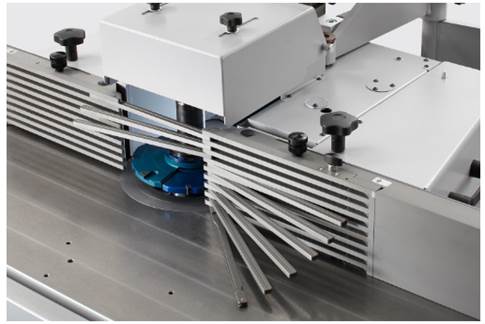

The fence opening should always be closed as much as possible, so that the workpiece can be safely guided and slide along the fence. Both are provided by the tried-and-tested Aigner Integral fence. The bars of the jaws consist of hard-coated aluminium and can be easily folded in position, released and also varied in height. The height of the bar cassettes is adjustable and they are easy to remove to enable working with a wooden insert.

The fence opening should always be closed as much as possible, so that the workpiece can be safely guided and slide along the fence. Both are provided by the tried-and-tested Aigner Integral fence. The bars of the jaws consist of hard-coated aluminium and can be easily folded in position, released and also varied in height. The height of the bar cassettes is adjustable and they are easy to remove to enable working with a wooden insert. -

For circular saw blades with diameters between 150 and 800 mm Riving knives correspond to DIN standard 38820 and can be correctly adjusted in Suva and DIN riving knife holders. Correctly adjusted riving knives significantly reduce the danger of work - pieces being violently ejected from the machine.

-

New Safety Guard for Circular Saws: This new saw guard rises and falls with the sawblade and independently from the blade when timber passes underneath the blade improving safety and guarding standards. Supplied complete with 2.8 mm 27175 riving knife. Technical Specification: Max saw diameter 315 mm Minimum saw diameter 250 mm Dust outlet size 35 mm

New Safety Guard for Circular Saws: This new saw guard rises and falls with the sawblade and independently from the blade when timber passes underneath the blade improving safety and guarding standards. Supplied complete with 2.8 mm 27175 riving knife. Technical Specification: Max saw diameter 315 mm Minimum saw diameter 250 mm Dust outlet size 35 mm -

Special over head crown guard assembly with integral extraction point. Suitable for attaching to existing or new support for saws up to 450mm diameter. Manufactured by SUVA, the Swiss safety executive. This guard is very popular as it can rise and fall as the material passes underneath helping to improve safety and accuracy. We can supply a complete range of mounting systems allowing this to be fitted to any saw up to the maximum capacity.

Special over head crown guard assembly with integral extraction point. Suitable for attaching to existing or new support for saws up to 450mm diameter. Manufactured by SUVA, the Swiss safety executive. This guard is very popular as it can rise and fall as the material passes underneath helping to improve safety and accuracy. We can supply a complete range of mounting systems allowing this to be fitted to any saw up to the maximum capacity. -

The SUVAmatic planer guard offers a new safe system for guarding protecting the cutter block when planing timber on surfacers or planer thicknessers. Practical workpiece guiding system: The workpiece guiding system consists of a pressure pad and a guide for the workpiece Both are fitted to the tip of the guard.

The SUVAmatic planer guard offers a new safe system for guarding protecting the cutter block when planing timber on surfacers or planer thicknessers. Practical workpiece guiding system: The workpiece guiding system consists of a pressure pad and a guide for the workpiece Both are fitted to the tip of the guard.