- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness

Woodworking Machinery – Laser Edgebanders

Technology for connecting edge material and the workpiece by Laser radiation

At the edge banding with laser technology, a predetermined layer of the Edging material becomes melted by laser radiation. While pressing the Edges onto the panel in the Pressure Zone, the melted material infiltrates into the edges of the workpiece and forms after cooling a jointless transition between edging and panel. Accordingly, there is no visible joint between the surface finish of the panel and the edge.

-

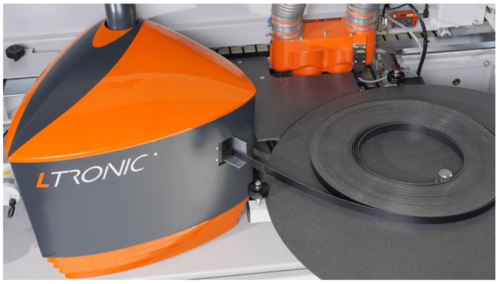

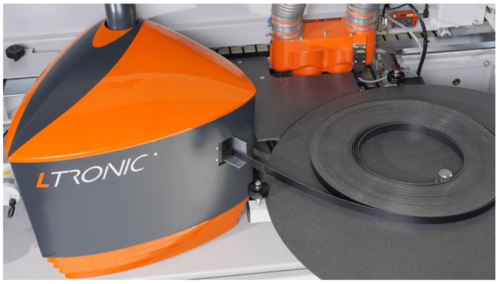

HOLZ-HER LUMINA Series: LTRONIC for Perfect Invisible Joints with Laser Edging HOLZ-HER's LUMINA 1380 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets

HOLZ-HER LUMINA Series: LTRONIC for Perfect Invisible Joints with Laser Edging HOLZ-HER's LUMINA 1380 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets -

LTRONIC and GLU JET - invisible joints in double pack! HOLZ-HER's LUMINA 1584 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets

LTRONIC and GLU JET - invisible joints in double pack! HOLZ-HER's LUMINA 1584 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness

-

Edgebander LUMINA 1586: Laser Edging Technology with two Cutter Units HOLZ-HER's LUMINA 1586 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets

Edgebander LUMINA 1586: Laser Edging Technology with two Cutter Units HOLZ-HER's LUMINA 1586 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness

-

HOLZ-HER LUMINA 1588: Laser Edging Technology with Special Units The LUMINA 1588 is a future-oriented milestone for edgebanders. Designed for absolute maximum performance, the ACCURA 1558 performance remains highly flexible, allowing adaptation to your specific requirements. Two cutter units, one corner buffing unit as well as one free space for an optional grooving unit are standard features in addition to the classic machining units. Up to 30 NC servo-axes move your high performance units to the specific machining position at the touch of a button Adaptive package for intelligent automation With this package the machine automatically sets

HOLZ-HER LUMINA 1588: Laser Edging Technology with Special Units The LUMINA 1588 is a future-oriented milestone for edgebanders. Designed for absolute maximum performance, the ACCURA 1558 performance remains highly flexible, allowing adaptation to your specific requirements. Two cutter units, one corner buffing unit as well as one free space for an optional grooving unit are standard features in addition to the classic machining units. Up to 30 NC servo-axes move your high performance units to the specific machining position at the touch of a button Adaptive package for intelligent automation With this package the machine automatically sets- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness

-

Perfectly invisible joints with laser edging Co-extruded and subsequently coated "Laser Edging" can be processed with Ltronic. The NIR module in our LTRONIC unit can transfer heat energy quickly and precisely to the specific point required making it ideal for activation of function layers on laser edging.

Perfectly invisible joints with laser edging Co-extruded and subsequently coated "Laser Edging" can be processed with Ltronic. The NIR module in our LTRONIC unit can transfer heat energy quickly and precisely to the specific point required making it ideal for activation of function layers on laser edging.- Visually perfect results – tone in tone with invisible joints.

- No heat-up time.

- Noiseless processing.

- No cleaning work.

- Pioneer in terms of energy efficiency.