Woodworking Machinery – Hotmelt Edgebanders

Hotmelt Edgebanding is produced with an extruder, a machine that consists of a loading system for raw materials, a screw inside a barrel that melts and transports the raw materials (plastics PVC, ABS, PP, PMMA and color pigments) through a die which shapes the edgebanding into the required size. After the Edgebanding is extruded, it can be texturized, printed, and lacquered to provide the required finish. The Edgebanding is then rolled and send to customers. Leading thermoplastic Edgebanding manufacturers worldwide are Doellken and Rehau with local manufacturers present.

-

Track Fed Edgebander for up to 2mm edgetape with finishing units Pull out support for large panels Glue pot with easy interchangeable system. First pressure roller roller is driven. End trimming unit with 2 sawblades Pneumatic guillotine capable of cutting coils up to 2 mm Multifunctional trimming unit with high frequency motors (bevel and radius 2mm) For a perfect finish the machine is equipped with vertical and horizontal copying devices. The KM550 is equiped with glue scrapers Max thickness of panel 8-50mm Max thickness of edgetape 0.4-2mm Teflon Coated Gluepot Chain fed track Numerical indicators for adjustments

Track Fed Edgebander for up to 2mm edgetape with finishing units Pull out support for large panels Glue pot with easy interchangeable system. First pressure roller roller is driven. End trimming unit with 2 sawblades Pneumatic guillotine capable of cutting coils up to 2 mm Multifunctional trimming unit with high frequency motors (bevel and radius 2mm) For a perfect finish the machine is equipped with vertical and horizontal copying devices. The KM550 is equiped with glue scrapers Max thickness of panel 8-50mm Max thickness of edgetape 0.4-2mm Teflon Coated Gluepot Chain fed track Numerical indicators for adjustments -

PLC Controller

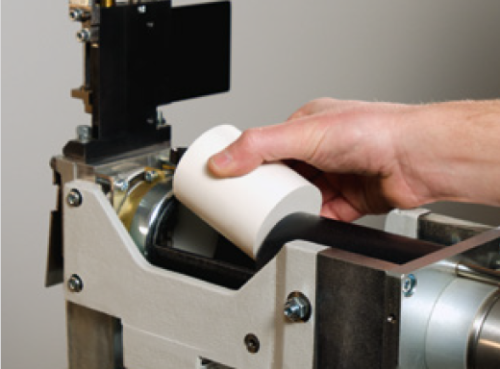

Teflon Coated Glue Pot

Pressure Roller

Pneumatic end trimming unit

Pneumatic guillotine capable of cutting coils up to 2 mm

Top and bottom trimming unit for radius 2mm

Available in Single Phase (220v)

Max thickness of panel 10-45mm

Max thickness of edgetape 0.4-2mm

Teflon Coated Gluepot

E321 Brochure -

PLC Controller

Teflon Coated Glue Pot

Pressure Roller

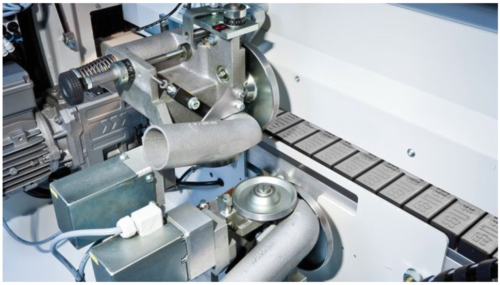

Chain type feed with rubber track pads

Motorised end trimming unit

Pneumatic guillotine capable of cutting coils up to 3 mm

Top and bottom High Frequency trimming unit for radius 2mm

Options:

Premilling with diamond cutters

Radius scrapers

Glue Scrapers

Buffers

Vertical rounding

Sprayers

Infra Red Lamps

Available in Single Phase (220v)

Max thickness of panel 8-45mm

Max thickness of edgetape 0.4-3mm

Max thickness of strips 5mm

Teflon Coated Gluepot

Brochure -

Leister Blower (3.4kW) Pressure Roller Pneumatic end trimming unit Pneumatic guillotine capable of cutting coils up to 2 mm Top and bottom trimming unit for radius 2mm Available in Single Phase (220v) Max thickness of panel 10-45mm Max thickness of edgetape 0.4-2mm Leister Hot Air Blower for pre-glued edgetape

Leister Blower (3.4kW) Pressure Roller Pneumatic end trimming unit Pneumatic guillotine capable of cutting coils up to 2 mm Top and bottom trimming unit for radius 2mm Available in Single Phase (220v) Max thickness of panel 10-45mm Max thickness of edgetape 0.4-2mm Leister Hot Air Blower for pre-glued edgetape

-

Glue pot with easy interchangeable system. First pressure roller roller is driven. Pneumatic end trimming unit Pneumatic guillotine capable of cutting coils up to 2 mm Multifunctional trimming unit with high frequency motors (bevel and radius 2mm) For a perfect finish the machine is equipped with vertical and horizontal copying devices. Available in Single Phase (220v) Max thickness of panel 8-50mm Max thickness of edgetape 0.4-2mm Teflon Coated Gluepot Chain fed track Numerical indicators for adjustments

Glue pot with easy interchangeable system. First pressure roller roller is driven. Pneumatic end trimming unit Pneumatic guillotine capable of cutting coils up to 2 mm Multifunctional trimming unit with high frequency motors (bevel and radius 2mm) For a perfect finish the machine is equipped with vertical and horizontal copying devices. Available in Single Phase (220v) Max thickness of panel 8-50mm Max thickness of edgetape 0.4-2mm Teflon Coated Gluepot Chain fed track Numerical indicators for adjustments -

Edgebander for up to 2mm edgetape with finishing units Pre-miling station: composed out of two motors. Standardly equipped with 2 diamonds cutters

Edgebander for up to 2mm edgetape with finishing units Pre-miling station: composed out of two motors. Standardly equipped with 2 diamonds cutters Pull out support for large panels

Omron Touch Screen controller and PLC

Glue pot with easy interchangeable system.

First pressure roller roller is driven.

End trimming unit with 2 sawblades

Pneumatic guillotine capable of cutting coils up to 2 mm

Multifunctional trimming unit with high frequency motors (bevel and radius 2mm)

For a perfect finish the machine is equipped with vertical and horizontal copying devices.

The KM550 is equiped with glue scrapers

Product Brochure

Pull out support for large panels

Omron Touch Screen controller and PLC

Glue pot with easy interchangeable system.

First pressure roller roller is driven.

End trimming unit with 2 sawblades

Pneumatic guillotine capable of cutting coils up to 2 mm

Multifunctional trimming unit with high frequency motors (bevel and radius 2mm)

For a perfect finish the machine is equipped with vertical and horizontal copying devices.

The KM550 is equiped with glue scrapers

Product Brochure -

High-tech with minimum space requirements and convincing performance spectrum for high quality edging work. The Streamer 1053 is equipped with the patented HOLZ-HER Glu Jet S system.

High-tech with minimum space requirements and convincing performance spectrum for high quality edging work. The Streamer 1053 is equipped with the patented HOLZ-HER Glu Jet S system.- Glue is applied exactly as required. This saves costs and optimises quality.

- The glue does not discolour or burn, since only the required amount of glue is melted in the closed system.

- One particular strength is the simple cartridge exchange. This makes it possible to change over from EVA to PUR glues or to different colours of glue quickly and rationally.

- Extremely short heat-up time of 3 minutes.

-

High-tech with minimum space requirements and convincing performance spectrum for high quality edging work. The Streamer 1057 is equipped with the patented HOLZ-HER Glu Jet system, pre-milling and corner rounding.

High-tech with minimum space requirements and convincing performance spectrum for high quality edging work. The Streamer 1057 is equipped with the patented HOLZ-HER Glu Jet system, pre-milling and corner rounding.- Glue is applied exactly as required. This saves costs and optimises quality.

- The glue does not discolour or burn, since only the required amount of glue is melted in the closed system.

- One particular strength is the simple cartridge exchange. This makes it possible to change over from EVA to PUR glues or to different colours of glue quickly and rationally.

- Extremely short heat-up time of 3 minutes.

-

High-tech with minimum space requirements and convincing performance spectrum for high quality edging work. The Streamer 1057 XL is equipped with the patented HOLZ-HER Glu Jet system and spraying devices.

High-tech with minimum space requirements and convincing performance spectrum for high quality edging work. The Streamer 1057 XL is equipped with the patented HOLZ-HER Glu Jet system and spraying devices.- Glue is applied exactly as required. This saves costs and optimises quality.

- The glue does not discolour or burn, since only the required amount of glue is melted in the closed system.

- One particular strength is the simple cartridge exchange. This makes it possible to change over from EVA to PUR glues or to different colours of glue quickly and rationally.

- Extremely short heat-up time of 3 minutes.

-

Highest degree of automation with two finishing units The Auriga 1308 is equipped with the patented HOLZ-HER Glu Jet system, pre-milling and corner rounding.

Highest degree of automation with two finishing units The Auriga 1308 is equipped with the patented HOLZ-HER Glu Jet system, pre-milling and corner rounding.- Glue is applied exactly as required. This saves costs and optimises quality.

- The glue does not discolour or burn, since only the required amount of glue is melted in the closed system.

- One particular strength is the simple cartridge exchange. This makes it possible to change over from EVA to PUR glues or to different colours of glue quickly and rationally.

- Extremely short heat-up time of 3 minutes.

-

Highest degree of automation with three finishing units The Auriga 1308 XL is equipped with the patented HOLZ-HER Glu Jet system and spraying devices.

Highest degree of automation with three finishing units The Auriga 1308 XL is equipped with the patented HOLZ-HER Glu Jet system and spraying devices.- Glue is applied exactly as required. This saves costs and optimises quality.

- The glue does not discolour or burn, since only the required amount of glue is melted in the closed system.

- One particular strength is the simple cartridge exchange. This makes it possible to change over from EVA to PUR glues or to different colours of glue quickly and rationally.

- Extremely short heat-up time of 3 minutes.

-

Superior Competency for Edgebanding HOLZ-HER SPRINT 1327: Maximum Productivity - Variable Feed and Shortest Workpiece Intervals Adaptive package for intelligent automation With this package the machine automatically sets

Superior Competency for Edgebanding HOLZ-HER SPRINT 1327: Maximum Productivity - Variable Feed and Shortest Workpiece Intervals Adaptive package for intelligent automation With this package the machine automatically sets- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness