Woodworking Machinery – Edgebanders

What is Edge banding used for?

Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material. Common substitutes for edgebanding include face frames or molding.

-

HOLZ-HER ACCURA Series: 100% Repetition Accuracy and Multifunctional The ACCURA 1558 performance is a future-oriented milestone for edgebanders. Designed for absolute maximum performance, the ACCURA 1558 performance remains highly flexible, allowing adaptation to your specific requirements. Adaptive package for intelligent automation With this package the machine automatically sets

HOLZ-HER ACCURA Series: 100% Repetition Accuracy and Multifunctional The ACCURA 1558 performance is a future-oriented milestone for edgebanders. Designed for absolute maximum performance, the ACCURA 1558 performance remains highly flexible, allowing adaptation to your specific requirements. Adaptive package for intelligent automation With this package the machine automatically sets- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness

-

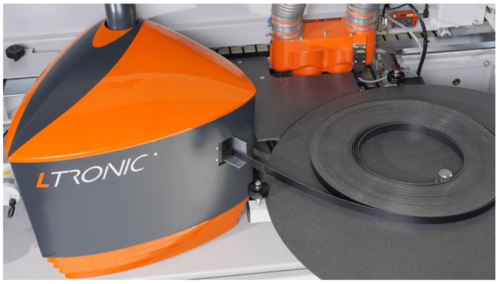

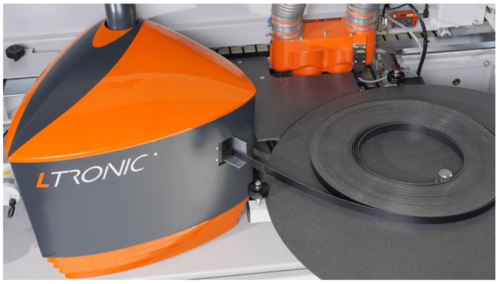

HOLZ-HER LUMINA Series: LTRONIC for Perfect Invisible Joints with Laser Edging HOLZ-HER's LUMINA 1380 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets

HOLZ-HER LUMINA Series: LTRONIC for Perfect Invisible Joints with Laser Edging HOLZ-HER's LUMINA 1380 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness

-

LTRONIC and GLU JET - invisible joints in double pack! HOLZ-HER's LUMINA 1584 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets

LTRONIC and GLU JET - invisible joints in double pack! HOLZ-HER's LUMINA 1584 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness

-

Edgebander LUMINA 1586: Laser Edging Technology with two Cutter Units HOLZ-HER's LUMINA 1586 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets

Edgebander LUMINA 1586: Laser Edging Technology with two Cutter Units HOLZ-HER's LUMINA 1586 offers a unique combination for processing panels: Two systems for perfectly invisible joints. The GluJet glue application system for standard use of PUR glue and the LTRONIC, the new laser edging unit from HOLZ-HER, are unbeatable in terms of speed and cost efficiency. Adaptive package for intelligent automation With this package the machine automatically sets- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness

-

HOLZ-HER LUMINA 1588: Laser Edging Technology with Special Units The LUMINA 1588 is a future-oriented milestone for edgebanders. Designed for absolute maximum performance, the ACCURA 1558 performance remains highly flexible, allowing adaptation to your specific requirements. Two cutter units, one corner buffing unit as well as one free space for an optional grooving unit are standard features in addition to the classic machining units. Up to 30 NC servo-axes move your high performance units to the specific machining position at the touch of a button Adaptive package for intelligent automation With this package the machine automatically sets

HOLZ-HER LUMINA 1588: Laser Edging Technology with Special Units The LUMINA 1588 is a future-oriented milestone for edgebanders. Designed for absolute maximum performance, the ACCURA 1558 performance remains highly flexible, allowing adaptation to your specific requirements. Two cutter units, one corner buffing unit as well as one free space for an optional grooving unit are standard features in addition to the classic machining units. Up to 30 NC servo-axes move your high performance units to the specific machining position at the touch of a button Adaptive package for intelligent automation With this package the machine automatically sets- Automatic glue quantity control

- Guillotine pressure according to thickness of edgetape

- Adaptive pressure on edgetape according to thickness

-

Perfectly invisible joints with laser edging Co-extruded and subsequently coated "Laser Edging" can be processed with Ltronic. The NIR module in our LTRONIC unit can transfer heat energy quickly and precisely to the specific point required making it ideal for activation of function layers on laser edging.

Perfectly invisible joints with laser edging Co-extruded and subsequently coated "Laser Edging" can be processed with Ltronic. The NIR module in our LTRONIC unit can transfer heat energy quickly and precisely to the specific point required making it ideal for activation of function layers on laser edging.- Visually perfect results – tone in tone with invisible joints.

- No heat-up time.

- Noiseless processing.

- No cleaning work.

- Pioneer in terms of energy efficiency.

-

High-tech with minimum space requirements and convincing performance spectrum for high quality edging work. The Streamer 1054 is equipped with the patented HOLZ-HER Glu Jet S system and corner rounding. - Glue is applied exactly as required. This saves costs and optimises quality. - The glue does not discolour or burn, since only the required amount of glue is melted in the closed system. - One particular strength is the simple cartridge exchange. This makes it possible to change over from EVA to PUR glues or to different colours of glue quickly and rationally. - Extremely short heat-up time of 3 minutes. The Streamer 1054 is capable of applying coiled edging and solid strips up to 6mm thick Panel thickness 6-60 mm Powerful feed motor for driving transport belt. Equipped with HOLZ-HER's patented glue nozzle system - Heat-up time: 3 minutes Equipped with 2 x diamond pre-milling cutters for panels up to 60mm thick First pressure roller roller is driven. End trimming unit with 2 x 140mm diameter saw blade (flush and angled trimming) Multipurpose trimming unit for flush trimming and radius up to 6mm thick - Equipped with diamond tools Option of 2 of the below units: 1. Glue Scrapers 2. Radius Scrapers 3. Buffing unit

High-tech with minimum space requirements and convincing performance spectrum for high quality edging work. The Streamer 1054 is equipped with the patented HOLZ-HER Glu Jet S system and corner rounding. - Glue is applied exactly as required. This saves costs and optimises quality. - The glue does not discolour or burn, since only the required amount of glue is melted in the closed system. - One particular strength is the simple cartridge exchange. This makes it possible to change over from EVA to PUR glues or to different colours of glue quickly and rationally. - Extremely short heat-up time of 3 minutes. The Streamer 1054 is capable of applying coiled edging and solid strips up to 6mm thick Panel thickness 6-60 mm Powerful feed motor for driving transport belt. Equipped with HOLZ-HER's patented glue nozzle system - Heat-up time: 3 minutes Equipped with 2 x diamond pre-milling cutters for panels up to 60mm thick First pressure roller roller is driven. End trimming unit with 2 x 140mm diameter saw blade (flush and angled trimming) Multipurpose trimming unit for flush trimming and radius up to 6mm thick - Equipped with diamond tools Option of 2 of the below units: 1. Glue Scrapers 2. Radius Scrapers 3. Buffing unit -

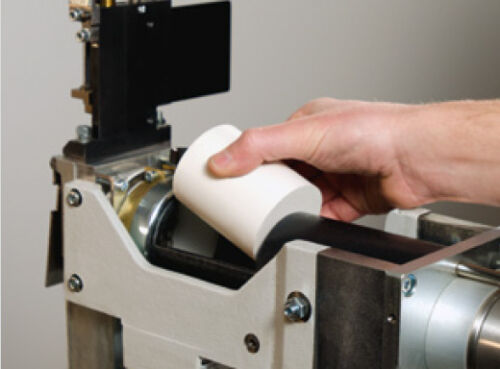

Invisible Joints with Glu Jet Thin Film Technology HOLZ-HER Glu Jet XL system For the ACCURA series HOLZ-HER offers the Glu Jet XL with greater melting capacity for even higher feed rates. With the Glu Jet XL, users can process 2 kg PUR glue cartridges, which are significantly more economical than conventional PUR granules. Product Brochure

Invisible Joints with Glu Jet Thin Film Technology HOLZ-HER Glu Jet XL system For the ACCURA series HOLZ-HER offers the Glu Jet XL with greater melting capacity for even higher feed rates. With the Glu Jet XL, users can process 2 kg PUR glue cartridges, which are significantly more economical than conventional PUR granules. Product Brochure -

EB-1 edgebander for use with pre-glued edging. Heat source via German made Steinel industrial heat gun with variable temperature control 100° - 200° C. Large rear table to support the coil of edging, working area with laminated surface and rubber covered pressure roller to ensure smooth and precise feeding of the workpiece. Fences and guides are fully adjustable for applying edging up to 55mm wide. Incorporated hand operated guillotine to cut off the coil.

-

Track Fed Edgebander for up to 2mm edgetape with finishing units Pull out support for large panels Glue pot with easy interchangeable system. First pressure roller roller is driven. End trimming unit with 2 sawblades Pneumatic guillotine capable of cutting coils up to 2 mm Multifunctional trimming unit with high frequency motors (bevel and radius 2mm) For a perfect finish the machine is equipped with vertical and horizontal copying devices. The KM550 is equiped with glue scrapers Max thickness of panel 8-50mm Max thickness of edgetape 0.4-2mm Teflon Coated Gluepot Chain fed track Numerical indicators for adjustments

Track Fed Edgebander for up to 2mm edgetape with finishing units Pull out support for large panels Glue pot with easy interchangeable system. First pressure roller roller is driven. End trimming unit with 2 sawblades Pneumatic guillotine capable of cutting coils up to 2 mm Multifunctional trimming unit with high frequency motors (bevel and radius 2mm) For a perfect finish the machine is equipped with vertical and horizontal copying devices. The KM550 is equiped with glue scrapers Max thickness of panel 8-50mm Max thickness of edgetape 0.4-2mm Teflon Coated Gluepot Chain fed track Numerical indicators for adjustments