Woodworking Machinery – Nesting CNC machines

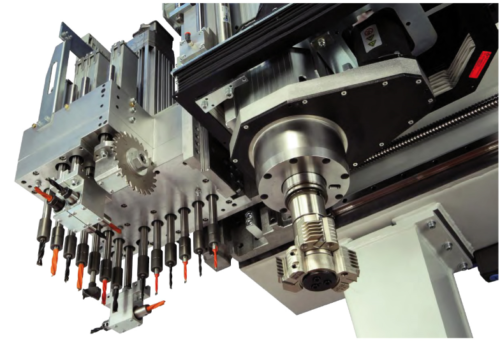

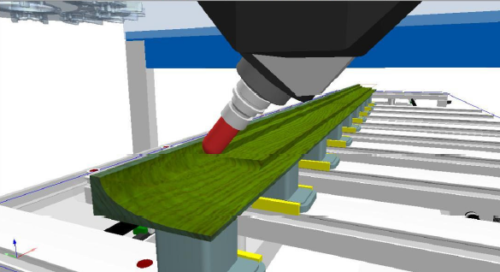

CNC nesting technology ensures efficient formatting and drilling on one machine. Here the panel is held by large-surface vacuum on a wear plate. The great advantage of this production method is production of exactly formatted workpieces, already provided with groove or rebate in the rear wall and all required vertical holes for shelves, connectors, etc. Above all the entire process is accomplished without additional handling work and is therefore extremely efficient in terms of time and resources.

-

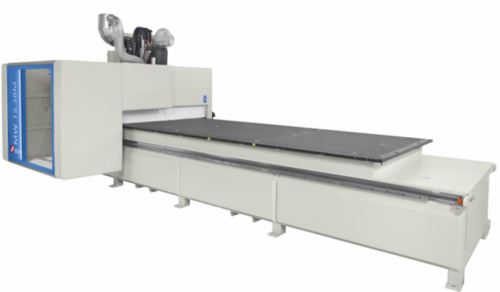

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure -

CNC machining center with 5 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure

CNC machining center with 5 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure -

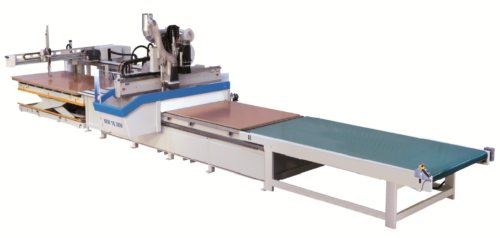

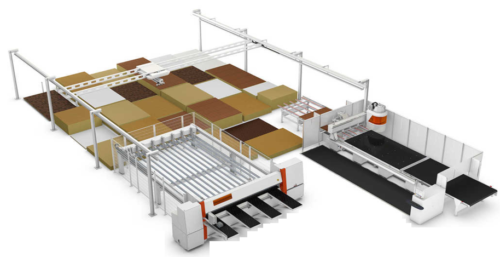

CNC machining center with 3/4 controlled axis equipped with automatic loading, labelling and automatic unloading for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm

CNC machining center with 3/4 controlled axis equipped with automatic loading, labelling and automatic unloading for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm -

The HOLZ-HER DYNESTIC 7521 Gantry machine has pushed the limits for nesting technology to new dimensions Bed sizes available: 3100mm x 2100mm 3900mm x 2100mm 4600mm x 2100mm 5600mm x 2100mm 6250mm x 2100mm Product Brochure

The HOLZ-HER DYNESTIC 7521 Gantry machine has pushed the limits for nesting technology to new dimensions Bed sizes available: 3100mm x 2100mm 3900mm x 2100mm 4600mm x 2100mm 5600mm x 2100mm 6250mm x 2100mm Product Brochure