Woodworking Machinery – CNC Machine Centres

CNC machines for solid wood and panels:

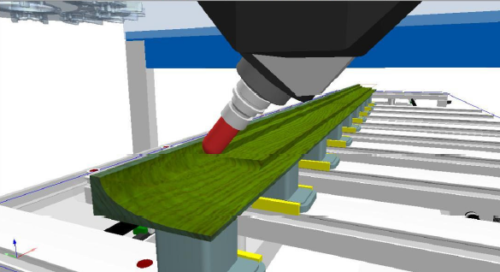

Investments in state-of-the-art CNC machines are worthwhile. Furniture and components even with complex designs can be produced economically and precisely. Latest generation control technology, drives and software ensure virtually unlimited possibilities. CNC machines designed for efficient and accurate machining of solid wood, panels, windows and doors, composite material and aerospace.

-

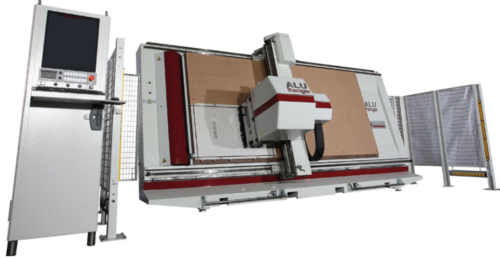

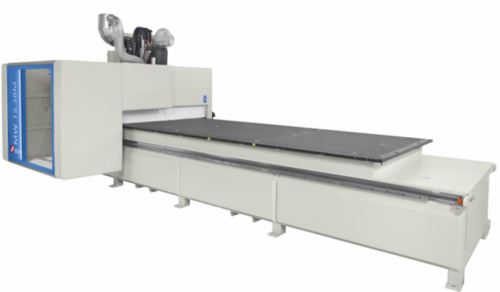

The HOLZ-HER DYNESTIC 7521 Gantry machine has pushed the limits for nesting technology to new dimensions Bed sizes available: 3100mm x 2100mm 3900mm x 2100mm 4600mm x 2100mm 5600mm x 2100mm 6250mm x 2100mm Product Brochure

The HOLZ-HER DYNESTIC 7521 Gantry machine has pushed the limits for nesting technology to new dimensions Bed sizes available: 3100mm x 2100mm 3900mm x 2100mm 4600mm x 2100mm 5600mm x 2100mm 6250mm x 2100mm Product Brochure -

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1250mm 3800mm x 1550mm 3800mm x 1850mm 3800mm x 2100mm Product Brochure

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1250mm 3800mm x 1550mm 3800mm x 1850mm 3800mm x 2100mm Product Brochure -

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure

CNC machining center with 3 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure -

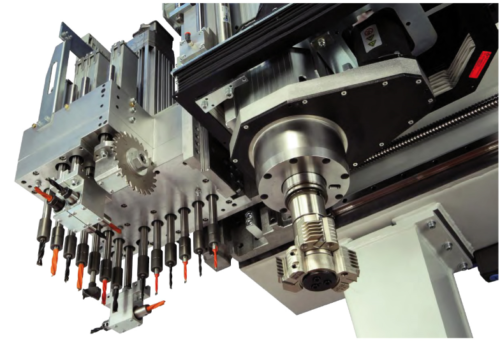

CNC machining center with 5 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure

CNC machining center with 5 controlled axis equipped with matrix table for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm Product Brochure -

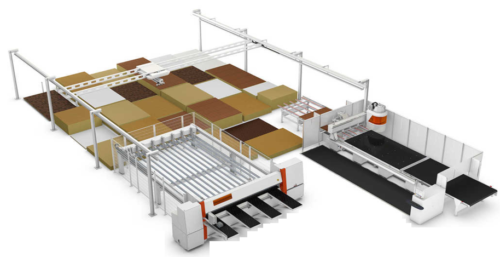

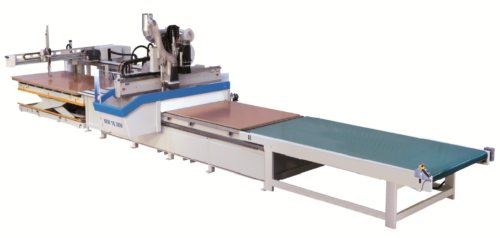

CNC machining center with 3/4 controlled axis equipped with automatic loading, labelling and automatic unloading for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm

CNC machining center with 3/4 controlled axis equipped with automatic loading, labelling and automatic unloading for nesting operations on wood or its derivatives, plastic or composite materials. Bed sizes available: 2500mm x 1300mm 3800mm x 1595mm 3800mm x 1845mm 3100mm x 2195mm 4200mm x 2195mm 6500mm x 2195mm -

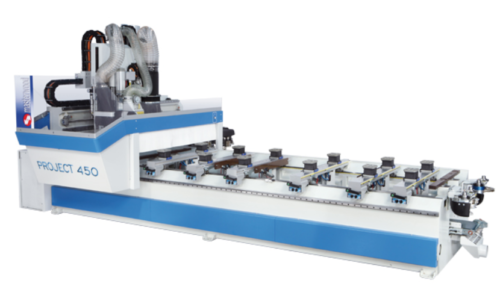

The CNC working center for high performance with small investment. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure

The CNC working center for high performance with small investment. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure -

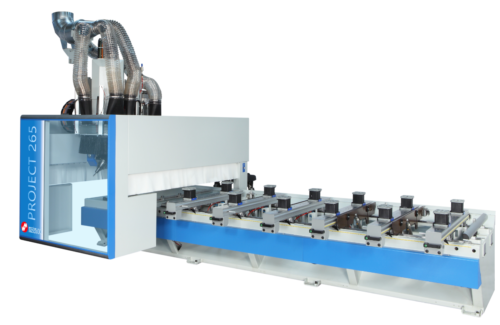

5-axis machining centre with “big” features: large workpiece clearance, stiffness and high precision. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table - Equiped with Master SetUp, a new worktable “computeraided” setup system! Product Brochure

5-axis machining centre with “big” features: large workpiece clearance, stiffness and high precision. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table - Equiped with Master SetUp, a new worktable “computeraided” setup system! Product Brochure -

Performance, flexibility, modularity and economy all concentrated in a 3 axis working center. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure

Performance, flexibility, modularity and economy all concentrated in a 3 axis working center. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure -

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table

Performance, flexibility, modularity and economy all concentrated in a 5 axis working center. The 5 axis spindle is mounted on an independent Z Axis “TUBELESS” TYPE WORKING TABLE - Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail - No risk of damaging pipes during machining - Time saving set up of work table -

Performance, flexibility, modularity and economy concentrated in a 3 axis working center. "Cantilever" structure for wide panels. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure

Performance, flexibility, modularity and economy concentrated in a 3 axis working center. "Cantilever" structure for wide panels. “TUBELESS” TYPE WORKING TABLE Versatile, easy and quick setting up with the possibility to place 8 suction cups on each rail No risk of damaging pipes during machining Time saving set up of work table Product Brochure